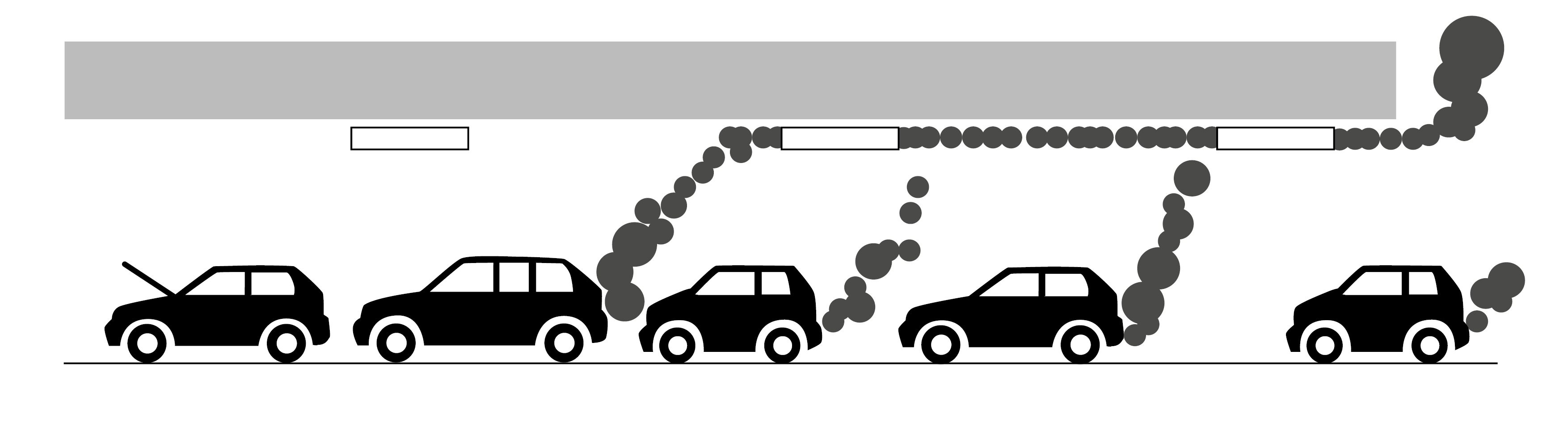

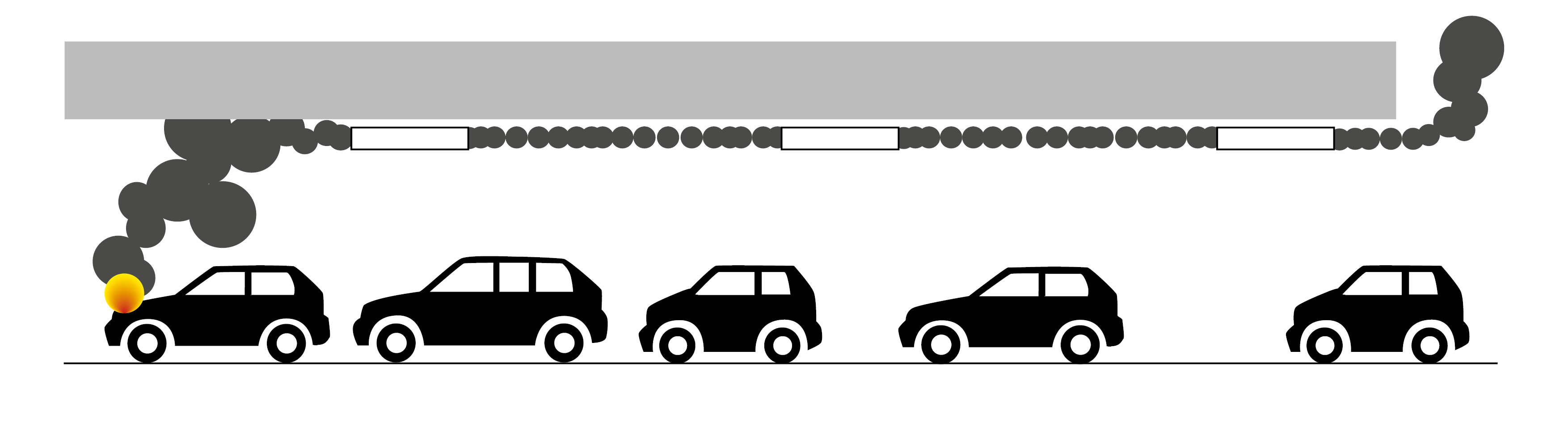

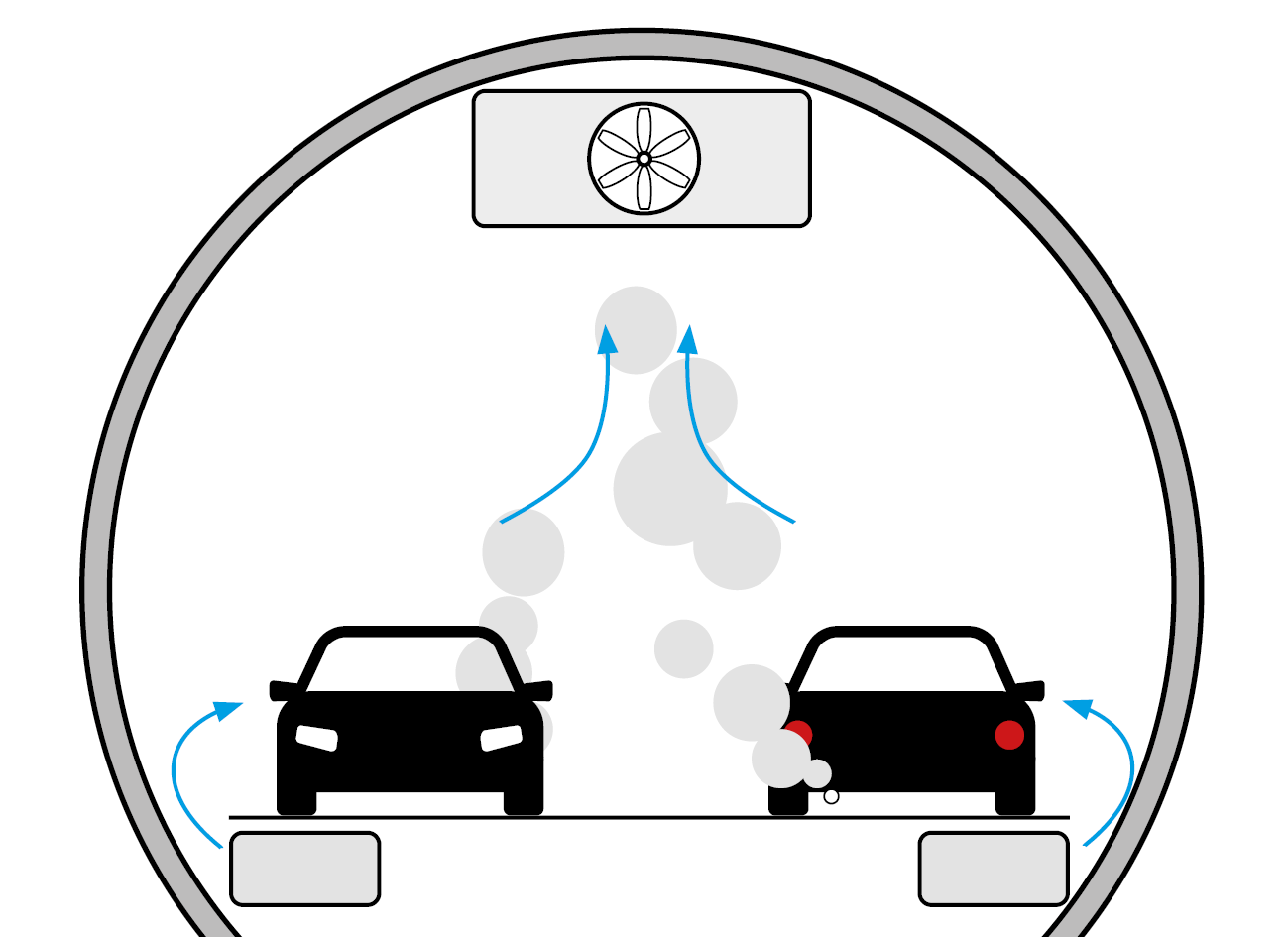

The accumulation of carbon monoxide, nitrogen dioxide, and other harmful gases in parts of a tunnel can make it impossible to breathe. It can also create a fog inside the tunnel, impairing visibility and increasing the risk of an accident - so it’s vital to have effective tunnel ventilation. Additionally, the right system will remove smoke and vitiated air in the case of a fire or an accident involving volatile components, ensuring safe evacuation, and providing access for emergency services.

Ventilation systems are also necessary for mitigating a tunnel’s environmental impact on its surroundings. Filters, dampers, and other equipment are used to reduce the effect on the air quality outside of the tunnel.

TUNNEL VENTILATION SOLUTIONS

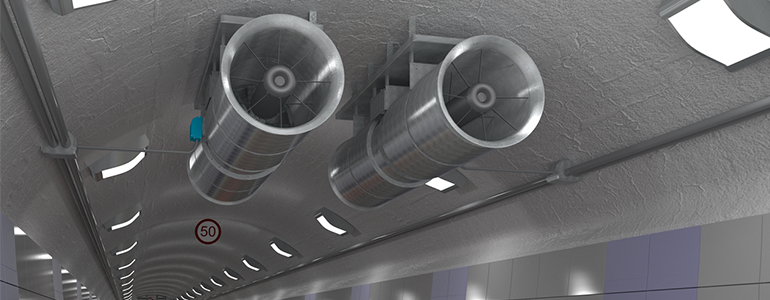

We design and manufacture bespoke systems for tunnel ventilation to remove harmful exhaust fumes and, in the event of a fire, to control smoke. We offer more than just a product; we have a team of experts who design optimum solutions, calculate pressure drop and noise, offer product witness testing, installation guidance, support and commissioning assistance in the UK and globally.

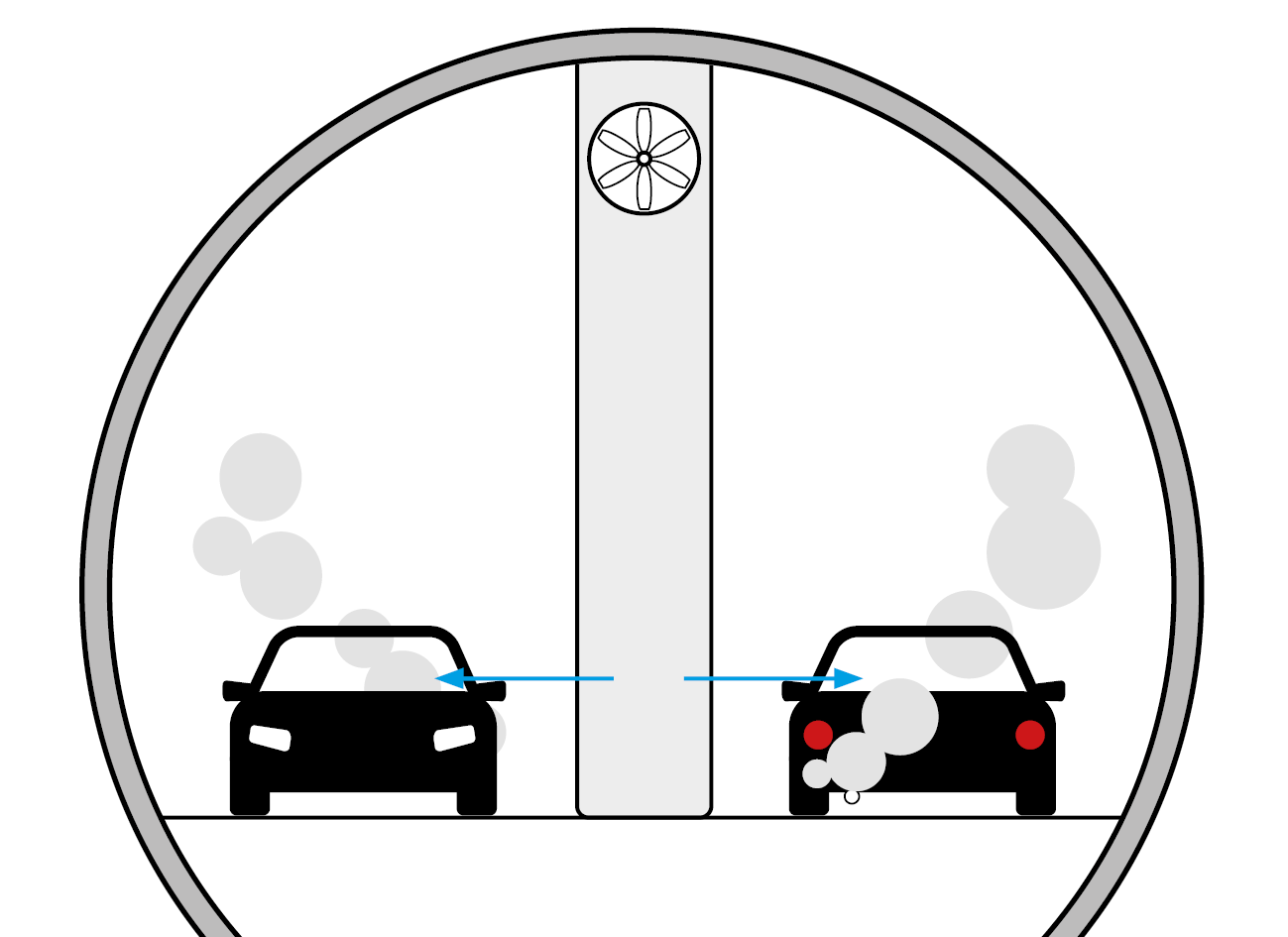

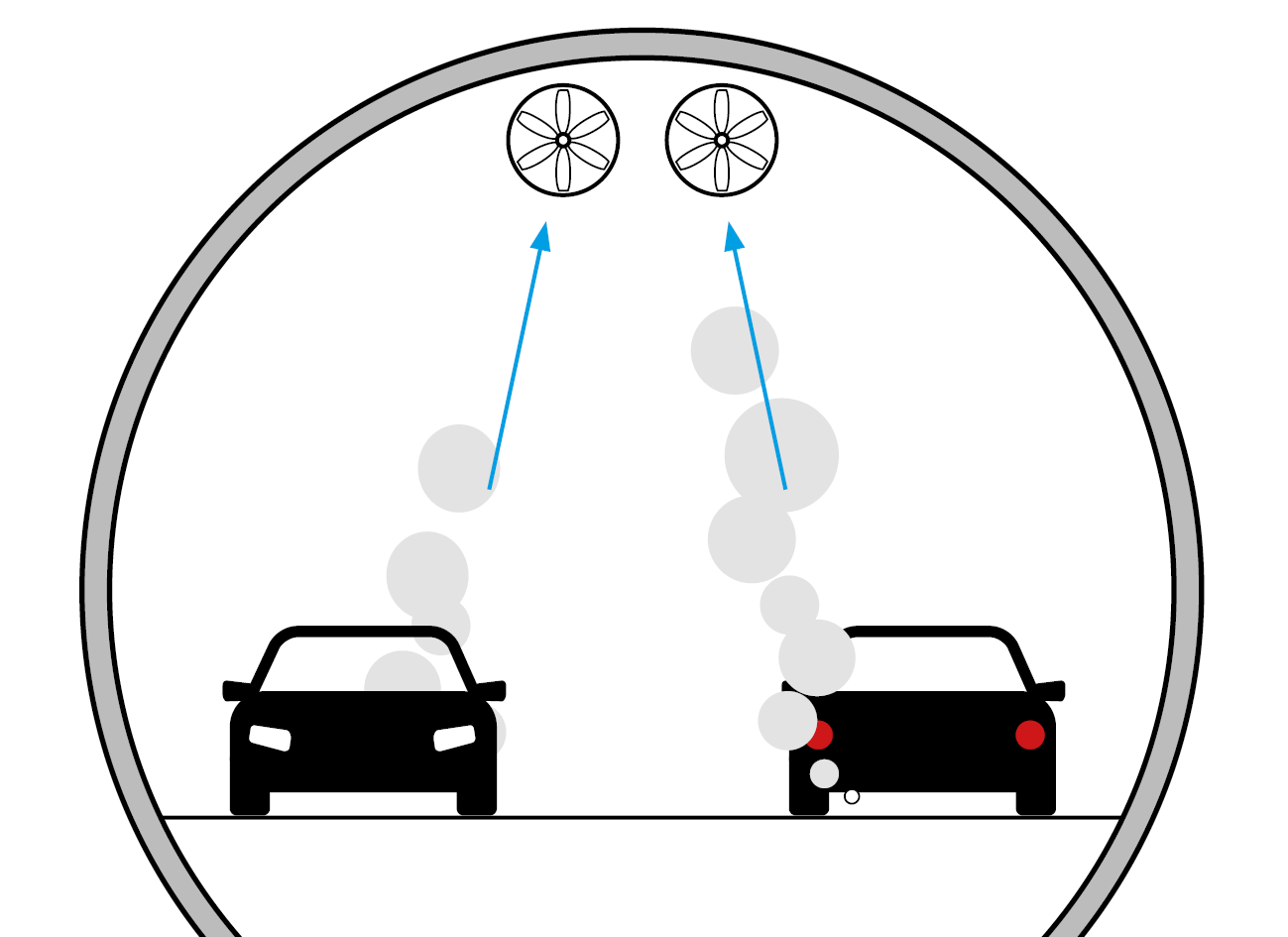

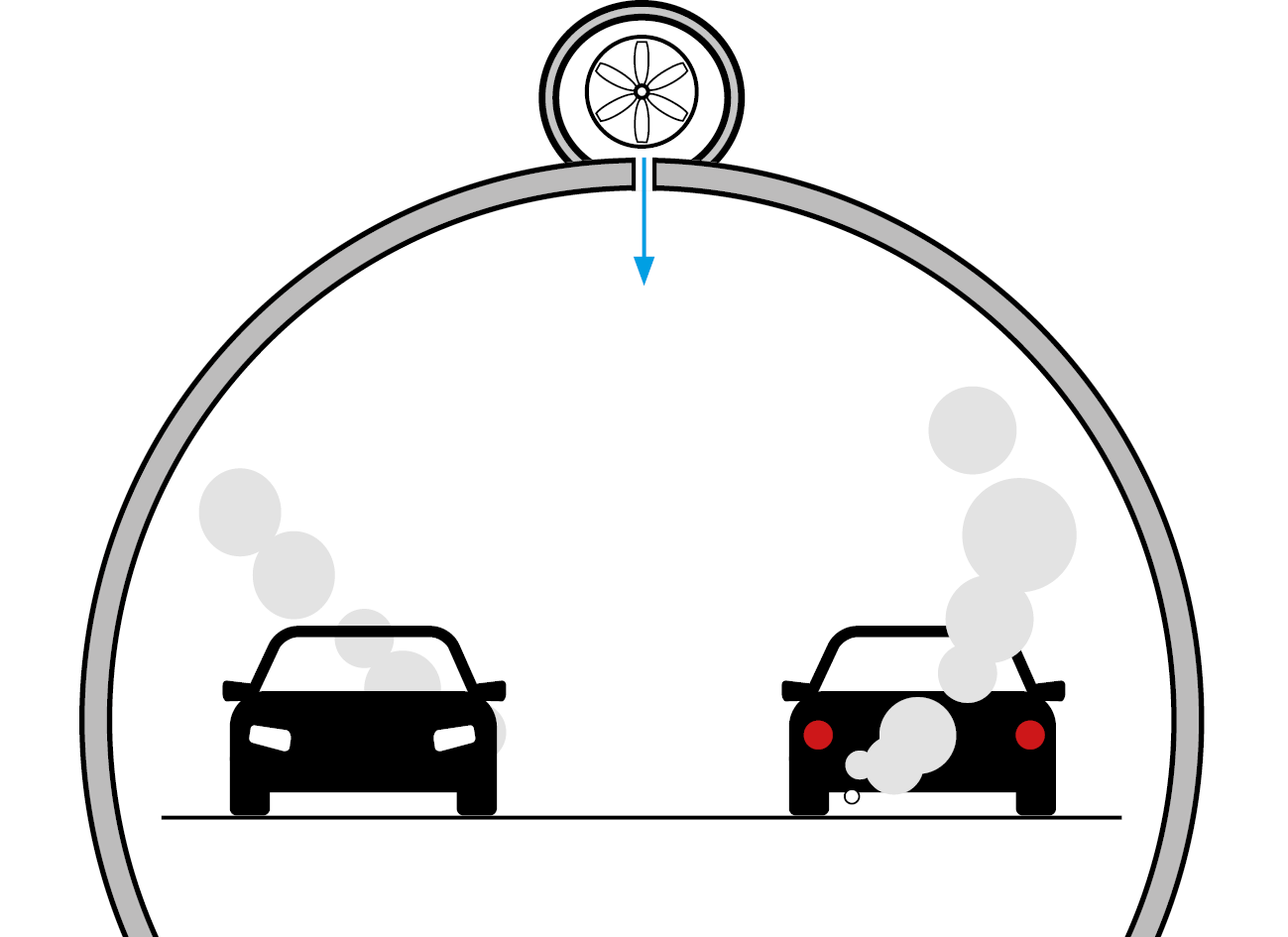

If your tunnels use Jet Fans, Large Axial Fans, Central Ventilation or a Saccardo Nozzle System, it is critical to choose a company and product with unrivalled engineering knowledge and application support.