World-class axial fans made in the UK

Woods Air Movement has one of the largest ranges of standard and high temperature certified Axial Fans available from any manufacturer: covering a wide range of applications including ventilation, smoke extraction, cooling and processing.

Axial Fans

JM Axial Fans

Aerofoil Axial Flow Fan

HT JM Axial Fans

HT Aerofoil Axial Flow Fan

JMv Axial Fan

Aerofoil Axial Flow Fan

HT JMv Axial Fan

HT Aerofoil Axial Flow Fan

JMTS Reversible Axial Fans

Reversible Axial Flow Fan

JMvG Axial Fan

Aerofoil Axial Flow Fan

JM 2 Stage Axial Fans

Aerofoil Axial Flow Fan

HT JM 2 Stage Axial Fans

HT Aerofoil Axial Flow Fan

MaXfan 2

Axial Fans

MaXfan Compac

Axial Fans

Woods Air Movement Axial Fans

Woods Air Movement has one of the largest ranges of standard and high temperature (HT) certified Axial Fans available from any manufacturer, covering a wide range of applications including ventilation, smoke extraction, cooling and processing.

What is an Axial Fan?

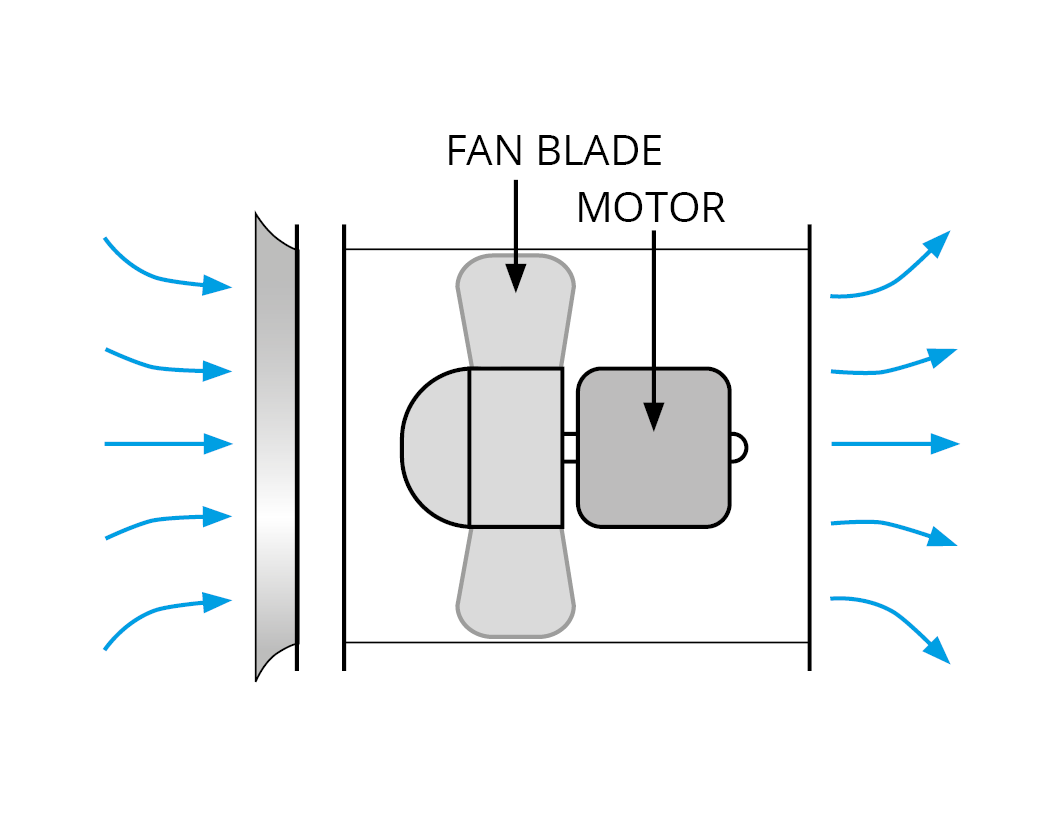

An axial fan is a fan type which moves gas (air, steam, fumes or smoke) through it in an axial direction - parallel to the shaft about which the blades rotate. The flow is axial at entry and exit. It is designed to produce a pressure differential which causes a flow through the fan - pulling air through the fan inlet. Factors which determine the performance of a fan include the number and shape of the blades and the speed at which they rotate. Design parameters include power, flow rate, pressure rise and efficiency. Performance is also dependant on the fan enclosure (casing) design.

Axial fans generally comprise fewer blades (two to six) than centrifugal fans and commonly have a larger radius and lower speed than ducted (in line) fans. They can be single or two-stage depending on the pressure required.

Axial fans have various blade designs including Aerofoil, Sickle, Paddle, and Variable pitch in motion.

WHAT ARE AXIAL FANS USED FOR?

Typical uses for Axial Fans include:

- Fire safety (smoke extraction and stairwell pressurisation) in commercial buildings

- Ventilation (supply & extract of hazardous fumes) in car parks and tunnels

- Factories and power plants, (cooling and extract fans)

- Commercial kitchens, food processing and storage

- Agriculture Livestock welfare and crop storage.

WHAT ARE THE DIFFERENT TYPES OF AXIAL FAN?

The Woods Air Movement axial fan range includes the highly configurable JM and JMv fans that can be configured to your requirements.

Tube Axial Fans – JM Range

Tube Axial fans have medium pressure, high flow capability and are not equipped with guide vanes. The JM is available in standard and high temperature variants from 315mm up to 1,600mm and can be used in a variety of configurations such as two-stage (for high pressure applications), short cased or long cased, ATEX and hazardous area.

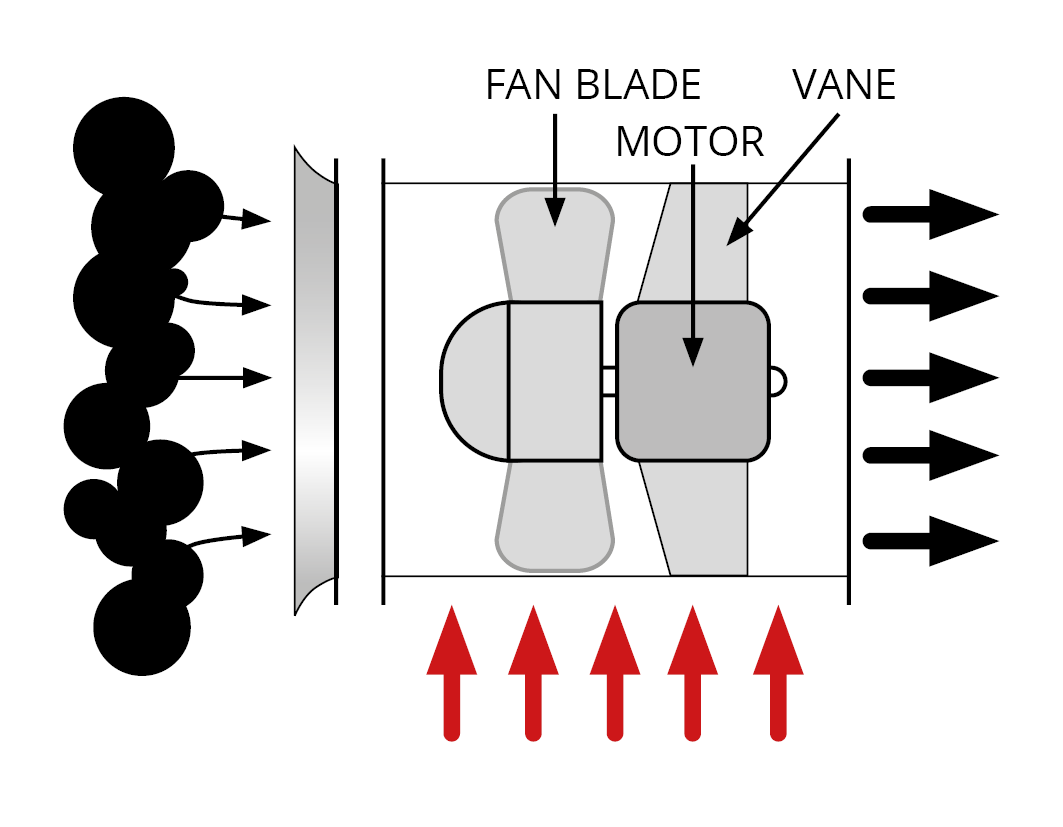

Vane Axial Fans – JMv Range

Vane-axial fans are equipped with inlet or outlet guide vanes to control the direction the air leaves the fan, and are characterised by high pressure, medium flow capabilities. The JMv is our cutting edge, high efficiency range of guide vane fans (vane axials) that deliver class-leading energy efficiency and can generate higher levels pressure. The JMv is also available in standard temperature or High Temperature (HT) EN 12101-3:2002 certified F200, F300 and F400.

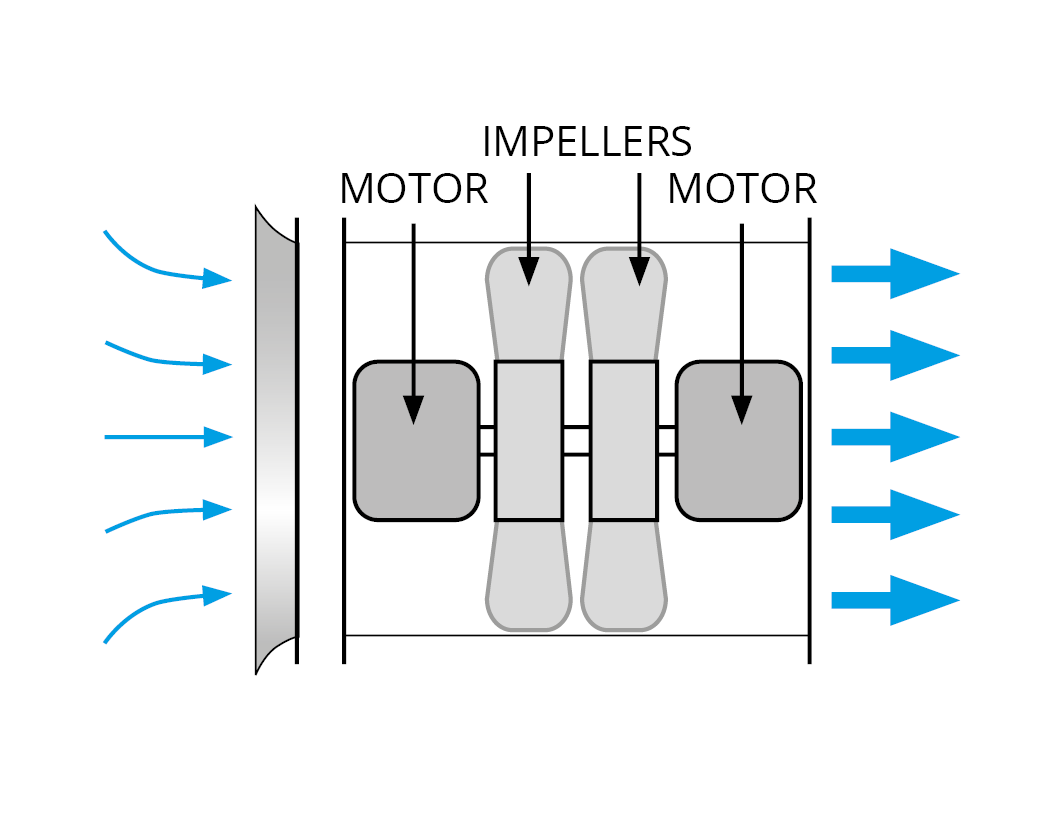

Two-Stage Axial Fans

2 stage fans have two impellers rotating in opposite directions at the same time, which generates up to 2.7 times the pressure development of a single fan. A two stage configuration delivers a high efficiency and high-pressure developing, in-line solution. MaXfan 2 provides one electrical connection point reducing installation time/connection costs, whilst the JM2 variant, features a duct-mounted terminal box for each stage.

High Temperature (HT) Fans

If a fan is being installed to provide enhanced fire safety, a high temperature variant is the essential choice. Designed to perform under extreme conditions, up to 400C, our HT Axial range is designed to remove hot smoke as rapidly as possible, for a duration of up to 2 hours, in order to provide valuable time to evacuate an area and help keep smoke levels down while firefighters control the fire.

As well as complete axial fans, we also supply our class leading impellers for OEM applications such radiator cooling.

FIND OUT MORE

To help you decide exactly which type of fan suits your requirements try our online Fan Selector Tool. For more information or to discuss your requirements, please get in touch.