Why should you X-Ray Fan Components?

Peace of mind

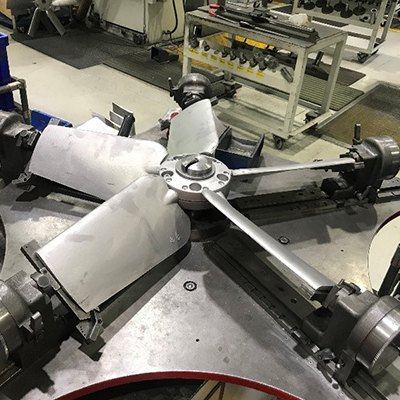

At Woods Air Movement we do a range of tests on parts to give our customers the peace of mind that they are buying quality fans from us. This is not something new and we have done it for many years! Quality is a part of everything we do at Woods Air Movement, and a cornerstone of our values. To ensure our quality, we perform a range of tests on our components and products.

Two of the quality tests we do:

- 100% X-ray all moving parts to ASTM E155

- Balance and Vibrations levels to ISO14694

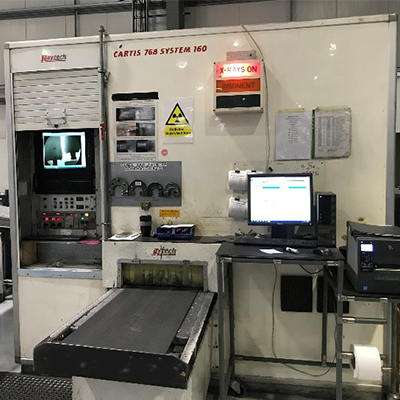

For X-ray testing, we have two machines inhouse for various size parts.

Small X-Ray Machine

Large X-Ray Machine

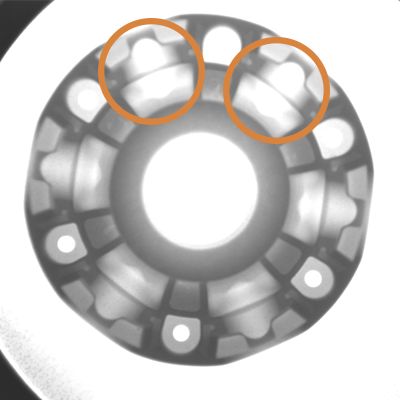

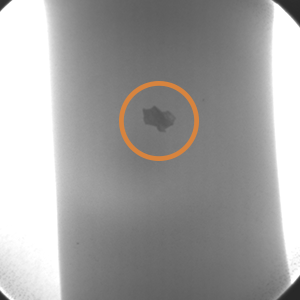

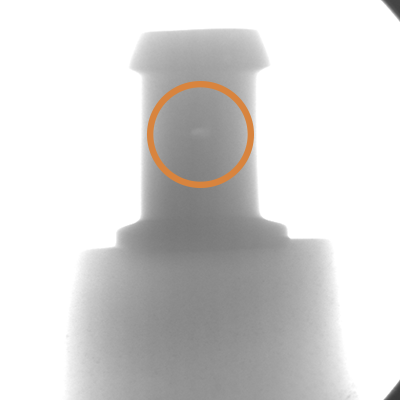

We provide our customers with products of the highest quality. To ensure there are no abnormalities we X-ray all moving parts. The abnormalities that we look for are small holes in the material, known as porosity, foreign contaminants or weak points which could cause a failure if used in a running fan. Here are some examples of parts where we have found some abnormalities:

Air Pockets

Foreign Objects

Air Pocket

If any abnormalities are identified the X-ray, we then throw these parts away and they do not get used. If a part has past the quality check through the X-ray machine, and been approved, we give the part a unique identifying number. The etched number you can see on a part is a reference to the X-ray image that was taken and archived in case a customer requests it in the future. Only after this process successfully completed are they ready be used in our fans.

Testing and quality checks are integral to our manufacturing processes and our Testing Laboratory is in constant use.

To find out more or to discuss your next project, please get in touch.

2024-06-06