UNDERSTANDING ATEX

What does ATEX mean for you?

What is ATEX?

ATEX is short for the French term ‘Atmosphères Explosibles’ and is the name commonly given to the two European Directives for controlling explosive atmospheres.

Explosive atmospheres can be caused by flammable gases, mists or vapours or by combustible dusts. If there is enough of the substance, mixed with air, then all it needs is a source of ignition to cause an explosion.

Explosions can cause loss of life and serious injuries as well as significant damage to property and equipment. Preventing releases of dangerous substances, which can create explosive atmospheres, and preventing sources of ignition are two widely used ways of reducing the risk. If the release of dangerous substances is unavoidable, extracting it from an enclosed environment with an ATEX-Certified Fan is another way of keeping risk to a minimum. EU-based ATEX Directives define and categorise the different hazardous environments to give specific and measurable standards for employers and manufacturers to work with.

In the UK Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) place duties on employers to eliminate or control the risks from explosive atmospheres in the workplace so it’s important to accurately assess and monitor your environment.

WHAT IS AN EXPLOSIVE ATMOSPHERE?

In DSEAR, an explosive atmosphere is defined as ‘a mixture of dangerous substances with air, under atmospheric conditions, in the form of gases, vapours, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture’.

Atmospheric conditions are also referred to as ambient temperatures and pressures. That is to say, temperatures of –20°C to 40°C and pressures of 0.8 to 1.1 bar.

WHERE CAN EXPLOSIVE ATMOSPHERES BE FOUND?

Many workplaces may contain, or have activities that produce, explosive or potentially explosive atmospheres. Examples include places where work activities create or release flammable gases or vapours, such as vehicle paint spraying, or in workplaces handling fine organic dusts such as grain, sugar, flour or wood.

WHAT ARE THE ATEX DIRECTIVES?

- Directive 99/92/EC (also known as 'ATEX 137' or the 'ATEX Workplace Directive') on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres.

- Directive 2014/34/EU (also known as 'ATEX 114' or the ‘ATEX Equipment Directive') on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

DEFINING AN EXPLOSIVE ATMOSPHERE

No fan can be provided without the correct ATEX classification of the hazards at play. It is down to the employer to undertake a thorough and accurate assessment to establish the following:

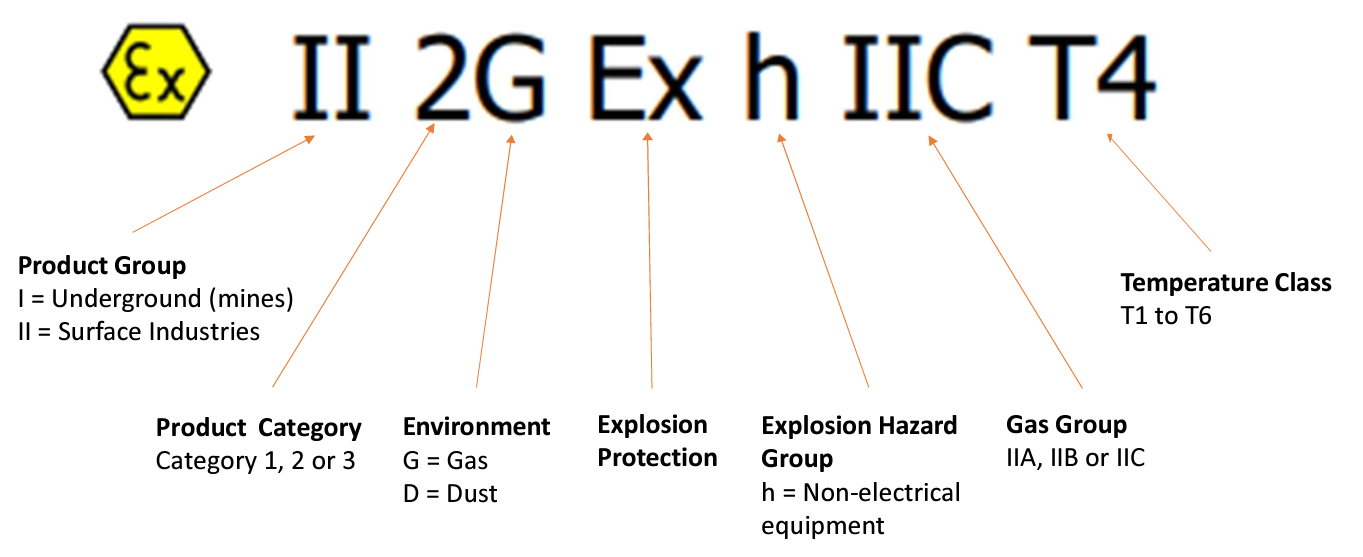

1 The Product Group

There are just two – I Underground (mines) and II Surface Industries

2 The Zones

Exactly how often is the area exposed to the explosive atmosphere? The recognised zones are;

| Gas | Dust | Definition |

| Zone 0 | Zone 20 | Continually present (typically >1000 hr/year) |

| Zone 1 | Zone 21 | Likely to occur in normal operation occasionally (typically 10 -1000 hr/year) |

| Zone 2 | Zone 22 | Unlikely to occur in normal operation (by accident), only for very short periods of time (typically <10 hr/year) |

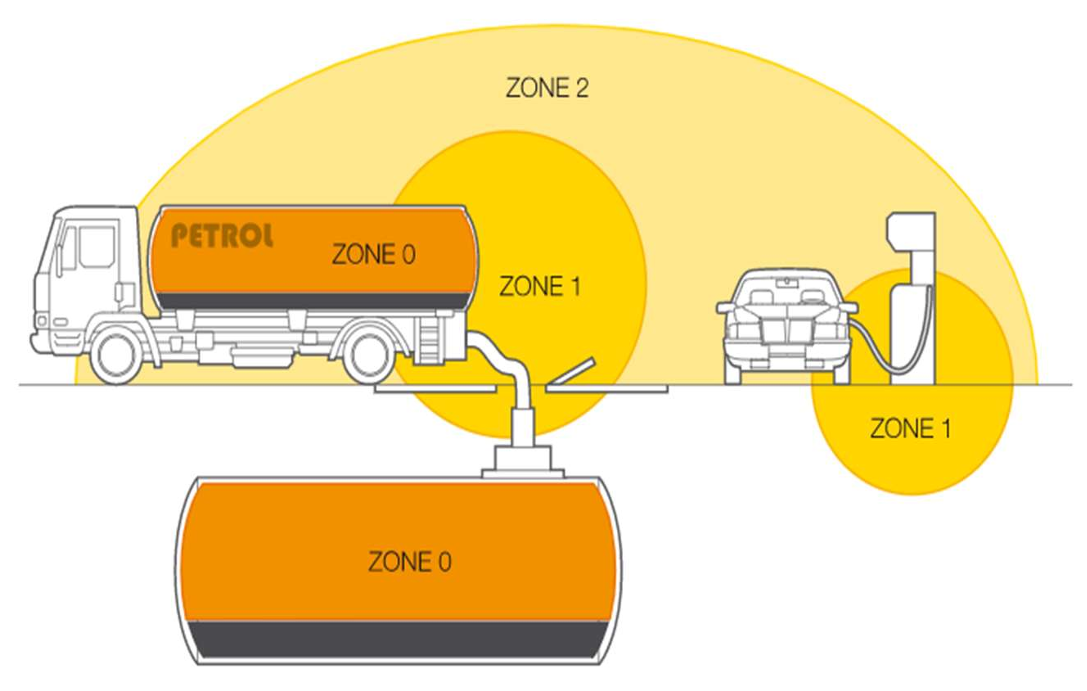

The simplest way to illustrate this is using an example of a petrol station:

In this example Zone 0 is where the fuel is stored and is a constantly explosive environment. Zone 1 is only dangerous while fuel is being pumped when fumes or splashes could occur. Zone 2 is rarely dangerous – in this case only in the event of a significant accidental spill.

3 The Degree of Protection

Having established the relevant zone for a given area, the ATEX directives then categorise equipment by its suitability for use in a given zone. Three categories of equipment are available with category 1 providing the highest degree of protection and category 3 the lowest. Categories are further denoted by either G (Gas) or D (Dust) depending on the nature of the hazard.

4 Explosive Risk

Gases and Dust are all categorised depending on their volatility or ease of ignition. They are grouped into 3 categories (A to C with C being the highest risk) AND classified by their ignition temperature (T1 to T6 with T6 being the lowest temperature and therefore the most dangerous).

ATEX LabelS

All this information is included on the product label and should be explained in the documentation that comes with the fan.

Our friendly experts can help you choose the correct ATEX fan for your environment – we offer a range of standard fans and can design and build bespoke ones for more extreme environments. To find out more get in touch today.

2024-06-10