What is a Centrifugal Fan?

Axial vs Centrifugal - what are the differences?

We take a look at the differences between an Axial Fan and a Centrifugal Fan and the applications they are used for.

What is a Centrifugal Fan?

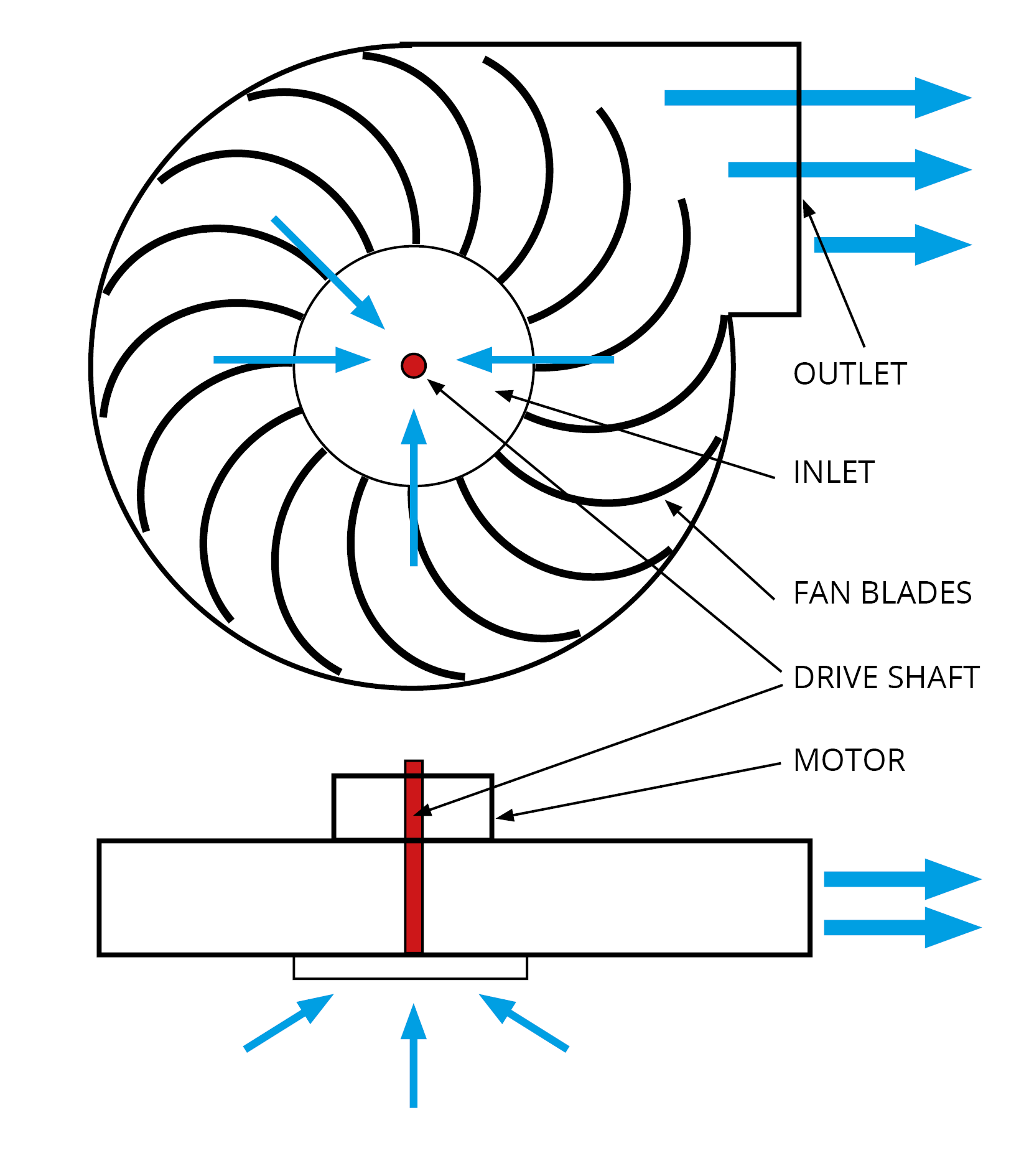

There are three basic types of fan – Axial fans, which pull air through in line with the shaft axis, Centrifugal fans which change the direction of the air or other gases by 90°, as the air flows from the fan inlet to the outlet, and Mixed Flow Fans which tend to be a hybrid of the Axial and Centrifugal concepts. As mixed flow fans are used for more specialist applications, the fan type choice is normally focused on either Axial flow or Centrifugal, dependant on the application.

Traditionally designed Centrifugal fans often feature a ducted housing (scroll or volute) to direct outgoing air in a specific direction; such a fan is also called a blower, blower fan, or squirrel-cage fan (because it looks like a hamster wheel). These fans move air from the rotating inlet of the fan to an outlet. They are typically used inline in ducted applications to either draw air through ductwork/heat exchanger or to push air through similar impellers. Compared to standard axial fans, they typically provide lower or similar air flow performance, but are able to develop higher pressures. Another variant is the 'plug fan', which is a caseless fan, designed to pressurise a plenum chamber (AHU fan section).

HOW DOES A CENTRIFUGAL FAN WORK?

A centrifugal fan impeller has a drum shape composed of a number of fan blades mounted around a central hub. Typical impeller blade construction types include Paddle, Radial, Backward Curved and Forward Curved. The hub turns on a driveshaft mounted in bearings in the fan housing. The air, gas or smoke enters from the centre of the fan wheel, turns 90 degrees and accelerates due to centrifugal force as it flows over the fan blades and exits the fan housing. Centrifugal fans are driven by induction motors – either AC or EC.

Like axial fans, centrifugal fans are constant-volume devices, meaning that, at a constant fan speed, they move a relatively constant volume of air rather than a constant mass. This means that the air velocity in a system is fixed, but the actual mass of air flowing will vary based on variations in gas/air density, which can be caused by changes to the incoming air temperature and elevation above sea level (altitude), making these fans unsuitable for applications where a constant mass of air is required to be provided – in equipment used at high altitude for example.

WHAT IS THE DIFFERENCE BETWEEN AN AXIAL FAN AND A CENTRIFUGAL FAN?

Centrifugal fans are often compared to axial fans for residential, industrial, and commercial applications. Axial fans typically operate at higher volumes, lower static pressures, and have higher operating efficiencies so are usually used for moving high volumes of air, such as warehouse exhaust or tunnel ventilation. Centrifugal fans are typically used to move air in ducted applications such as a commercial kitchen or office environment. Box fans usually have centrifugal fans housed within a cubed casing to allow flexibility on the direction of air travel while Car Park induction fans (ITFs) use Centrifugal fans to deliver a low height unit design, as head space is often limited within car parks. They can also be found in Roof Fans.

If you’d like to find out more or to discuss your next project, please get in touch today.

2024-06-21